Robots Free Humans from Repetitive Tasks

The holiday season is the busiest time of the year for online shopping. On Cyber Monday and Black Friday this year, Amazon sold more than one billion items, and Black Friday shopping sales totaled $9.8 billion. A typical Amazon Hub facility in Port Wentworth, Georgia processed more than 90,000 packages during the busy buying weekend, up from the typical 50,000 packages.

During the holiday season, Amazon (and all big retailers) ramp up hiring, but Amazon has been hit with complaints and lawsuits about unsafe working conditions. State labor regulators have fined Amazon for a workplace that exposes employees to increased risk of ergonomic injury and musculoskeletal disorders as they awkwardly bend and twist to move goods through the warehouse.

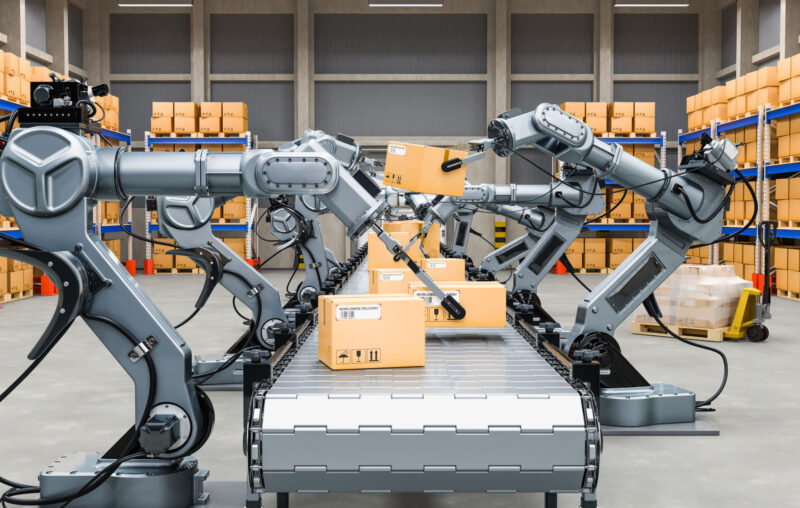

AI-powered robotics could alleviate injury rates and raise worker productivity, in addition to cooking food or writing academic essays. At Amazon, robots handle repetitive tasks or heavy lifting that cause substantial wear on the human body, reducing the risk of injury to employees. Robotics with AI would complement, rather than substitute, human labor.

Amazon today has 750,000 robots in its facilities, a decade after it acquired Kiva Systems. The workplace injury rate in facilities with robots has decreased by 15 percent in the past year.

Amazon’s containerized storage system uses robotics to figure out which mobile shelf or pod holds the container, find the container, and bring the container to the employee. This way, employees do not need to reach to retrieve items.

Amazon’s robotic handling systems, Cardinal and Sparrow, help employees during sorting. Cardinal sorts out the heavy packages (50 lbs) from totes or trays, reads the labels, and places them on a wheeled shelf. An employee does not have to lift and turn with a heavy object. Once an employee picks out the customer-ordered packages from a tote, Sparrow consolidates the existing inventory in different totes to return full totes to storage.

Amazon’s newest robot, Digit, complements Sparrow. It picks up and moves empty totes, another highly repetitive activity that creates wear and tear on the human body.

Proteus, an autonomous mobile robot, can navigate through a facility and move heavy objects. Launched in June 2022, it moves objects over 50 pounds across the wheeled shelves (GoCarts) in an Amazon facility. Proteus can do the bending and lifting, two activities that have higher rates of injury.

Furthermore, Amazon is experimenting with a multi-robot system called Sequoia at an Amazon facility in Houston, Texas. Sequoia delivers all the totes to employees at an ergonomic workstation, where the employee only has to do work between mid-thigh and mid-chest height. This innovation eliminates the need for regular reaching or squatting, further reducing the injury rate.

Sequoia has improved the identification and storage of incoming inventory by 75 percent, reducing the time to list and update inventory on Amazon.com. It has also reduced order processing time by 25 percent, speeding up shipping times.

With the implementation of robotics and AI, Amazon can reduce injuries and ship much faster. In some same-day facilities, packages “prepared for dispatch within 11 minutes of an order placement at same-day facilities,” about an hour faster than in next-day or two-day facilities.

AI also helps Amazon create efficient delivery routes, “adapting in real-time to traffic and weather conditions,” and helps Amazon forecast daily demand for packages so that the company can predict where and when things will be ordered. Delivery hubs can handle over 110,000 packages within the holiday season, up from the 60,000 that they typically handle.

AI and robotics will impact jobs and change various industries, but automation will first start to replace the jobs that people do not want to do. Robotics that incorporate AI speed up productivity in these manual tasks, just as machinery tripled farmer productivity at the turn of the 20th century. Robots excel at exactly the repetitive tasks that stultify the human mind and strain the human body. By incorporating robotics into its shipping system, Amazon raises efficiency and reduces worker injury rates. AI and automation have led to the creation of 700 new job types related to robotics at Amazon alone. Robotics could complement human labor and make work safer and more efficient.